Sale!

3.2kw ER20 water cooled spindle, VFD

₹45,750

- 3.2kw ER20 4 bearings water cooled spindle

- 4.0kw inverter/VFD

8 in stock

Description

Product Package:

- 3.2kw ER20 4 bearings water cooled spindle

- 4.0kw inverter/VFD

3.2kw Water Cooled Spindle Motor

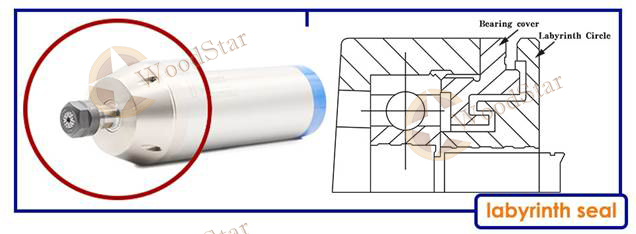

What is labyrinth seal?

There are 4 labyrinth seal in the front section of the spindle,Prevents lubricant leakage from bearings and intrusion of harmful impurities (dust, moisture, corrosive gases) and bearing seals under high-speed conditions.

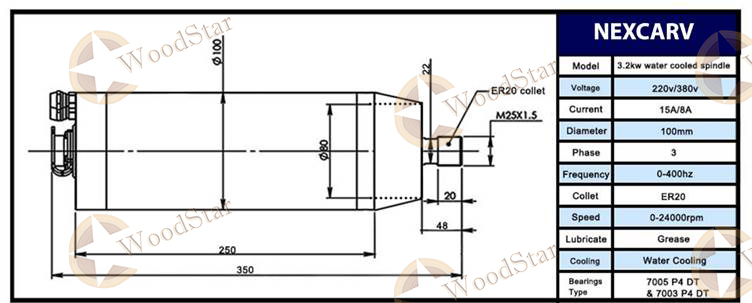

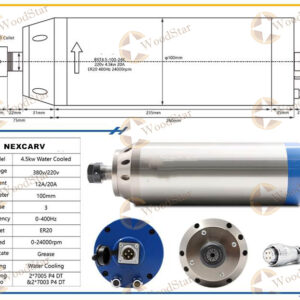

Basic parameters of 3.2kw Water cooled Spindle:

- Size: 100x250mm (Middle body diameter:100mm;Length:250mm)

- Speed Ways: Through 3-phase output inverter and adjust the inverter frequency to change the spindle speed.

- Cooling: Water cooling

- Power Interface: Optional H20-4 pins waterproof air plug. The air plug marked “1 “,”2″,” 3″,” 4″, “1 “,”2 “,”3” were connected to inverter (U, V, W), 4 connected inverter ground.

- Power: 3.0kw

- Voltage: 220v

- Current: 15A

- Frequency: 0-400Hz

- Speed: 0-24000rpm

- Runout Off: Less than 0.01mm

- Diameter(mm): 100

- Bearing Type: 2 x 7005 P4 DT & 2 x 7003 P4 DT

- 4pcs fully sealed angular contact bearings

- Collet: ER20

- Clip Knifediameter: 13mm,12mm,12.7mm,11mm,10mm,9mm,8mm,7mm, 6.35mm,6mm, 5mm, 4mm, 3.175mm, 3mm, 2mm, 1mm (standard 6mm)

- Water Cooling ER20 collet chunk

Main Application:

Engrave for wood,bamboo,normal PCB,PVC,PMMA,plastic,bamboo,duotone board(ABS)and etc nonmetal,also can engrave on gold,silver,copper,aluminium,Pb etc soft metal surface working.

Difference between Ceramic ball bearings and steel ball bearings:

- Our Ceramic ball bearings spindle use 4 pcs ceramic ball bearings.

- Ceramic ball bearings are resistant to high temperatures and low heat, usually 3-5 degrees lower than steel ball bearings during using.

- Ceramic ball bearings have low friction, low noise and long service life.

- If you want to use the spindle for aluminium, hard wood, then ceramic ball bearings better than steel ball bearings.

Spindle Advantages:

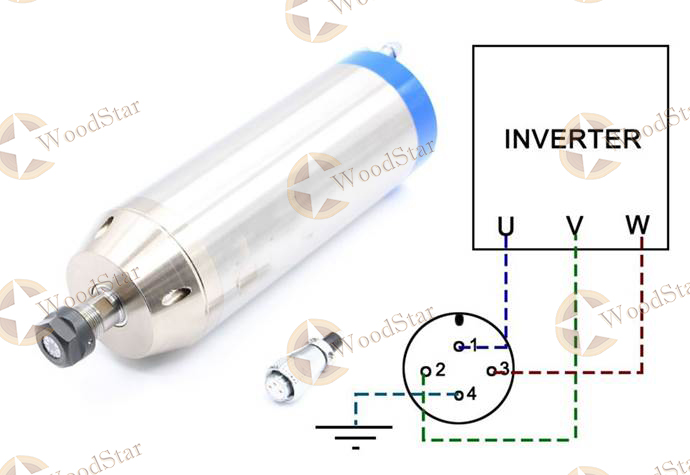

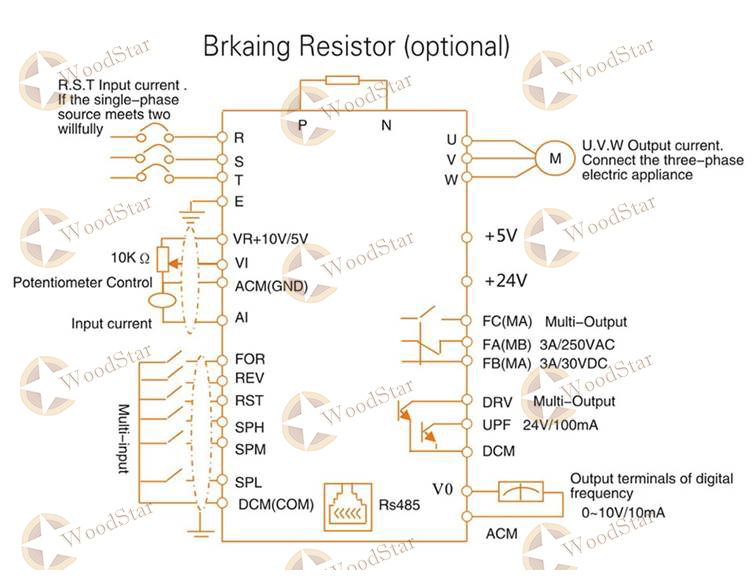

Spindle connect to inverter:

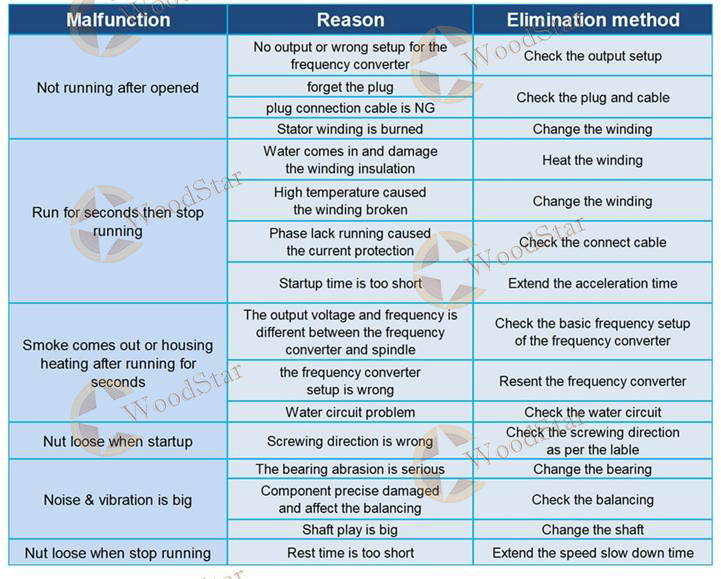

Problems and solutions:

Preparations before use:

- Spindle working environment temperature is usually -10 ~ 40 .

- Before installing the first electric spindle axis head turned by hand, should feel flexible, non-blocking phenomenon.

Use Correctly:

- Spindle in the preservation and transportation, high-speed grease inside the bearing state will change, customers should be running at low speed for 30 minutes. 3000 rpm and then follow the poor increase, run 20 minutes each. Spindle and the inverter should be working together. The inverter’s specifications and parameter settings need match spindles parameter.

- Connect the inverter spindle, three-phase inverter power cord should be soldered in the plug 1 (U), 2 (V), 3 (W) feet, 4 feet for the ground. After the power is turned on, to observe whether the spindle rotation axis indicates the direction consistent. If inconsistency should be immediately shut down, replace the inverter and spindle connected two wires of three-phase power supply.

- It should ensure that before use of water-cooled spindle, the cooling system is working properly. Every day before using the spindle must be running at low speed for 15-20 minutes. Clamping the cutters to spindle, collet nuts ,collets,cutters must be clean enough. Shank inserted into the collet must be greater than 15mm.

Care and Maintenance:

- Water cooled spindle MUST be used with water pump. Otherwise the spindle will soon broken.

- AC spindle motor MUST use with inverter. The power of inverter need equal or bigger than the spindle power. Before using,please set up the inverter parameters suitable for spindle. Otherwise the spindle and inverter will broken at once.

- When you use the spindle,the noise is not same as always,please STOP the spindle at once. You may need to replace the spindle bearings.

Water-cooled spindle and Air-cooled Spindle differences:

- Cooling in different ways: water-cooled spindle motor uses water cycle to cool the heat generated after the high-speed rotating spindle, whereas air cooled spindle motor uses fan-cooled approach for cooling.

- Noise: Water-cooled spindle motor is basically no noise, but the air-cooled spindle motor is very loud.

- Life aspects: Water-cooled spindle motor pay attention to maintenance, frequently changes the water or the use of industrial water coolers, air-cooled spindle fan mainly by the wind blowing the heat transferred to the heat sink, so as to achieve the cooling effect.

- If you need use for metal, hard wood, granite, stone, you can choose metal spindle, then metal spindle is much better than wood spindle.

4.0kw Inverter

Tech parameters:

- Inverter Type:Huanyang 220v 4.0kw

- Input Voltage: 220V(+/-15%)

- Output Voltage: 220vAC

- Input Frequency: 48-63 Hz

- Output Frequency: 0-400 Hz

- Input Phase: 1 or 3 phase

- Output Phase: 3 phase

- Warranty: 1 year from the date you purchased

Product Feature:

- PID control; advanced calculus PID closed-loop arithmetic, quick responding speed and high suitability;

- Easy PLC function can realize 16 legs of speed and inverter control function;

- RS485 communication port, adopting standard international MODBUS main circuit control;

- With extremely strong anti-jamming capability

- Low output ratting torque0.5HZ-150%, low speed running ability;

- Carrier adjustable by 16KHZ, completely soundless working environment;

- Broad voltage working area, normal running in 304V-456V;

- Auto voltage regulation (AVR) technique, for ensuring the inverter load capability;

- Various control technique by both synchronization and non-synchronization, dynamically realize fast starting without changing brakes;

- With perfect error protection and short circuit starting protection capability;

- Dead-time compensation and auto torque slip compensation function, can realize 180% high torque output at low frequency 0.25Hz;

- Unique EMC design, can minimize inverter’s pollution to power;

- Overall reinforcement layer to suit all kinds of harsh environment;

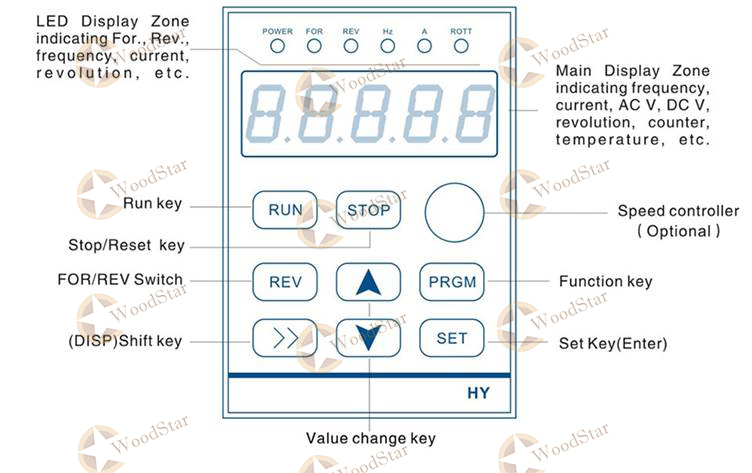

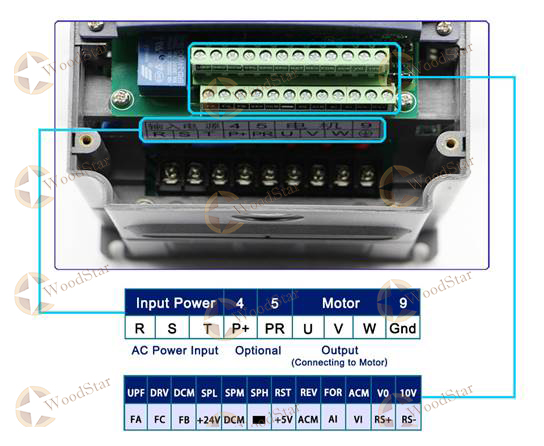

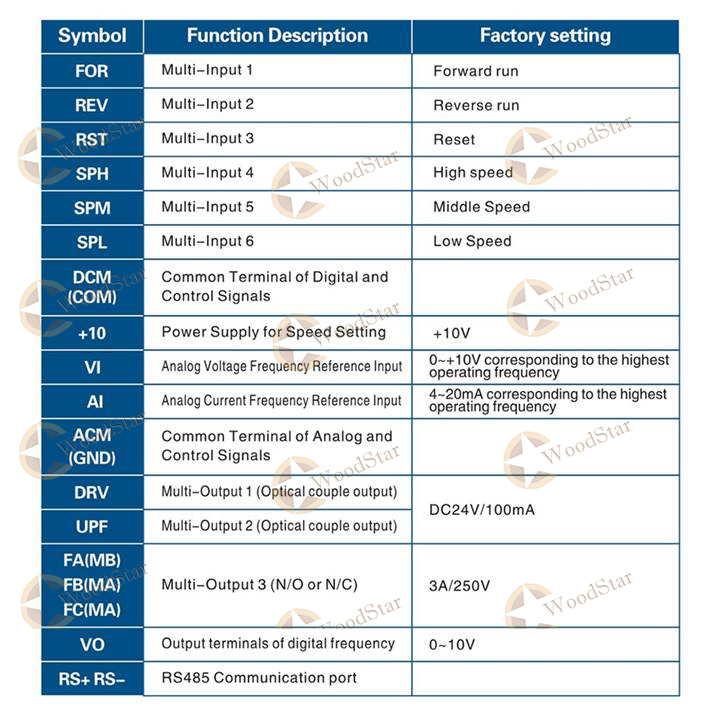

Inverter Details:

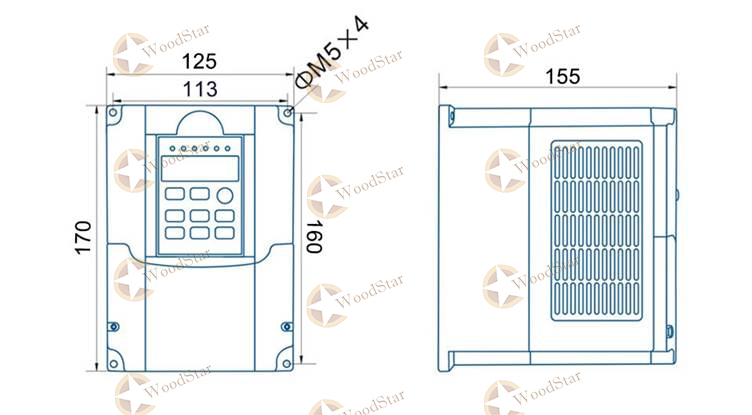

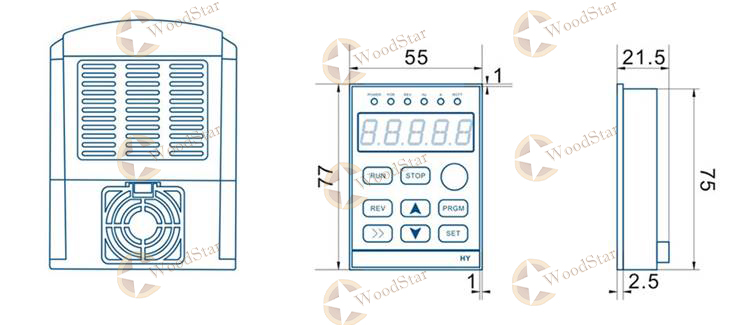

Dimension drawing:

Reviews

There are no reviews yet.